Thermodens Adaptive is the new Thermics range of wall-hung condensing boilers.

Excellent performance and high yields that last over time thanks to the innovative heat exchanger.

Ease of use thanks to the digital control panel with display designed to communicate with the user easily and comfortably.

Technical features

- Boiler with single-circuit stainless steel primary exchanger with nojunctions and/or welds that maintains high efficiency even on older systems

- New combustion system with patented gas-adaptive technology (Advanced Adaptive Gas Combustion Control A²GC²). The electronics continuously analyze the combustion (CO2) through the flame signal by acting on the gas valve and the fan, to ensure correct combustion in all conditions of use. The electronics allow the boiler to be easily adapted to the various types of gas without having to operate with mechanical transformation kits

- Instant production of sanitary hot water with dedicated plate exchanger

- Sanitary pre-heating function: faster hot water delivery

- User interface with display and multi-function keys for adjustment and parameter setting

- By-pass as standard, easy to inspect

- Chimney protection system: electronic management of flue gas overtemperatures, guaranteeing maximum chimney protection

- Intubation on flues: particularly suitable for operation in flues requiring intubation with high pressure drops

- Minimum polluting emissions (class VI - EN 15502-1)

- Sliding temperature operation optional external probe

- Low consumption modulating heating circulator (ErP Ready - Class A)

- Digital flame control with three reignition attempts in case of blocked operation due to lack of flame detection (methane configuration)

- Three-piece removable casing for easier maintenance or inspection

- For SV versions: possibility of setting the maximum power that can be delivered to the external tank

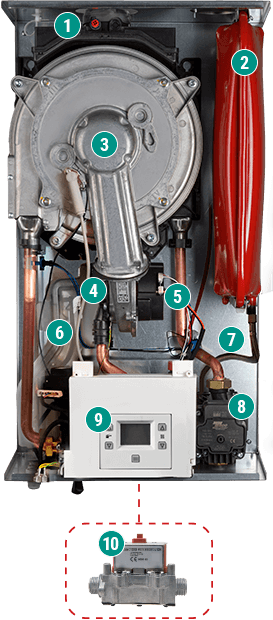

- 1. Double probe fumes safety

- 2. Expansion tank

- 3. Burner

- 4. Air/Gas mixer

- 5. Fan

- 6. Siphon condensate

- 7. Steel frame monocoque

- 8. Brass hydraulic unit

- 9. Control panel with Adaptive Gas electronic

- 10. Adaptive Gas Valve

Gas Adaptive Technology

Less consumption, less efficiency, less emissions

The innovative Adaptive Gas technology, which all Thermodens Adaptive models are equipped with boilers to different types and qualities of gas. As well as detecting the flame, the electrode also detects the characteristics of the gas and automatically adapts the combustion parameters to maintain maximum efficiency, with a consequent reduction in consumption and emissions compared to traditional control systems. The Adaptive gas system makes the boiler ready for operation for operation with any type of gas without any transformations.

- Automatic gas regulation

- Adaptation to gas quality change

- Clean combustion

- Only one model suitable for natural gas and LPG, that allows to optimize the warehouse

In traditional boilers the combustion values are detected and adjusted only when undergoing a maintenance. Moreover, the composition of mains gas is not always constant, and it can cause inefficiencies in the operation of the boilers that have no combustion control devices, undermining the reliability, the savings and the quality of emissions. Thanks to the Gas-Adaptive system, the new BTP condensing boilers control the combustion electronically, which allows them to best manage the gas and air supply at any time by automatically adjusting the CO2 level.

Control panel

- Winter/Summer/Off selector

- Heating temperature regulator

- DHW temperature regulator

- Digital pressure reading

- Screen display of DHW and heating temperature

- Display of fault diagnostics, lockout conditions and fault log

- Display of recommended filling and filling guide

- Display of annual maintenance expiry

- Enabling sanitary pre-heating

The display works in the following modes:

- INFO

Info mode displays the following information:

- Sanitary/heating temperatures choose by the user

- Flue gas temperatures

- Domestic water flow rate

- Fan speed

- Months remaining before maintenance

- Percentages of pump modulation

- Outdoor temperature (in case of connected outdoor probe)

- Value of K (in case of connected external probe) - PROGRAMMING

The programming mode allows you to modify the boiler parameters.

• BOILER PARAMETERS

Modification of boiler parameters

• HAMMER SWEEP

Possibility of setting 4 levels of boiler operation for combustion checks

• CALIBRATION

Automatic boiler calibration

• HYDRAULIC CIRCUIT DEAERATION

Facilitation for deaeration of the system in the installation phase

• HISTORY

List of errors recorded by the boiler during operation operation

Thermoregulation

Climatic adjustment (with optional external probe) and (remote) room adjustment to allow proper management of the water temperature in order to reduce consumption and consequently a reduction in emissions. The use of climate regulation also produces a rise in the regulation efficiency, increasing the value of your home.

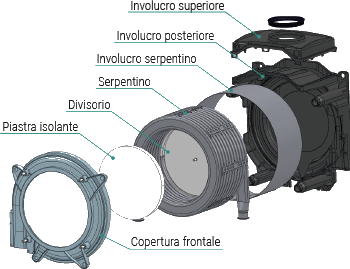

High circulation, mono spiral primary heat exchanger

Round is a compact monothermal heat exchanger based on a stainless-steel coil with an oval cross-section.

The heat exchanger consists of a combustion chamber, condensing zone and an insulated metal disc protected with silicon glass fibres separating the two areas. The use of a single stainless-steel belt to produce the coil, including the input/output connections, provides the following advantages:

- Accumulation of dirt and debris is prevented

- Water flow rate is distributed evenly and ensures a uniform thermal exchange

- The water flow rate is constant for the entire service life of the product

- Reduction in the head losses with optimised circuit

The robustness and ease with which these heat exchangers can be cleaned are just two of the strengths of the product given that it can be used on new installations as well as on an old system in the case of a substitution

Round integrates the round flow function in which the water produces a centrifugal effect for cleaning the internal walls of the mono spiral. The fact that there are no parallel circuits ensures easy “washing” operations of the heat exchanger and the elimination of any air present in the installation circuit.

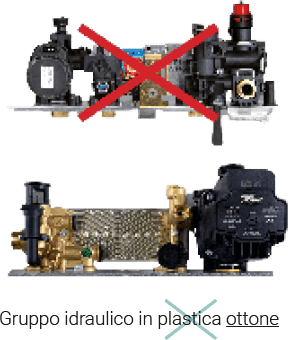

A Plastic-FREE production

For a sustainable environment

An important element that has managed the entire design phase of the Thermodens Adaptive boiler is a strong focus on the circular economy. This is why we used components with a higher recycling rate, eliminating the use of plastic as much as possible. The plastic assembly, for example, has been replaced with a brass assembly, which is fully recyclable. The boiler shells are made of cardboard instead of polystyrene.

Technical specifications

* With return water temperatures that do not allow condensation.

** With return water temperatures that allow condensation.

*** With coaxial flue outlet 60/100 L 0.9 m and METHANE G20 gas.

**** At minimum useful power.

***** Referred to EN 625 standard.

# Values referred to tests with 80 mm 1 + 1 split flue and methane gas G20.